Sylvester Manor Windmill with blades and sails in 1952 – photo by Andrew Fiske.

Sylvester Manor Windmill, April 26, 2021

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

SLYVESTER MANOR WINDMILL

RESTORATION PORTFOLIO

——————-

History: The Sylvester Manor windmill was originally built in Southold in 1810 by the renowned carpenter and millwright, Nathaniel Dominy V (1770-1852). As a fifth generation craftsman, Dominy worked on both the North and South Forks and had gained his reputation as a Master Carpenter after building the Hook Mill in East Hampton in 1806. The Sylvester Manor Mill was commissioned by partners Benjamin Horton, Moses Cleveland, Joseph Hallock and Barnabas Case several years later and originally operated in Southold grinding bushels of wheat, corn, rye and meslin.

In 1840 the mill was purchased by Joseph Congdon and moved to Shelter Island where it stood in the center of town near the present library. The new mill replaced a previous Shelter Island mill that had burned down years earlier. In 1855, the windmill was sold again to Smith Baldwin who continued to operate it until the 1870s. In 1879, Lilian Horsford, a descendant of the original Sylvester family, bought the mill to preserve it as an historic landmark.

The windmill resumed operation during World War I to help provide meal and flour to the inhabitants of Shelter Island at a time of severe food shortages. Cornelia Horsford, the youngest sister of Lilian, purchased the windmill from her in 1926 and had it moved to the highest elevation of Sylvester Manor, where it sits today. In 1952, Sylvester Manor owner Andrew Fiske renovated the windmill replacing the shingles and main driveshaft.

————————-

Restoration Phases

Restoration Phases: Phases 1 & 2 were completed over the past two years. Phase 1 included stabilizing the foundation by lifting the 6,000 pound structure six feet from its resting place for the first time in nearly 100 years in order to rebuild the foundation. New piers were poured and strapped to the undermounts. Phase 2 focused on the exterior — replacing eroded shingles and installing new doors and windows. Phase 3 was completed in 2021 by Master Craftsman Jim Kricker and his team of millwrights with the installation of a new windshaft and new blades.

“What we are doing here is removing the old windshaft first and then we will remove the old neck bearing. We will explore the beam under the neck bearing and are prepard to replace it if need be. Once that is done, the new windshaft goes in. The sails are made up of 6 pieces total. The backbone is made up of stocks. Two pieces go through the mortices of the windshaft to form a cross. The whips are the remaining 4 pieces that have lattice attached. Once assembled, they will be bolted to the stocks. Then, we will have an intact windmill, without the cloths.” — James Kricker, December, 2020.

Phase 4 includes bringing the windmill back to operational condition in 2021. This will address the mechanical parts of the windmill and related structural issues associated with supporting, aligning and operating the machinery.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Restoration Portfolio

Visit: www.sylvestermanor.org

———————— ADDENDUM ————————

The wood for the shaft was greenheart from Ghana.

“The crew went into the bush four separate times to get a log large enough for the axle. Even in the tropical rainforest, finding a tree that large (minimum 36” at 20’) in the species we need is a tough nut to crack. Greenheart is a large tree at breast height with a 36” diameter, and purpleheart even more so.” — James Kricker.

—————————

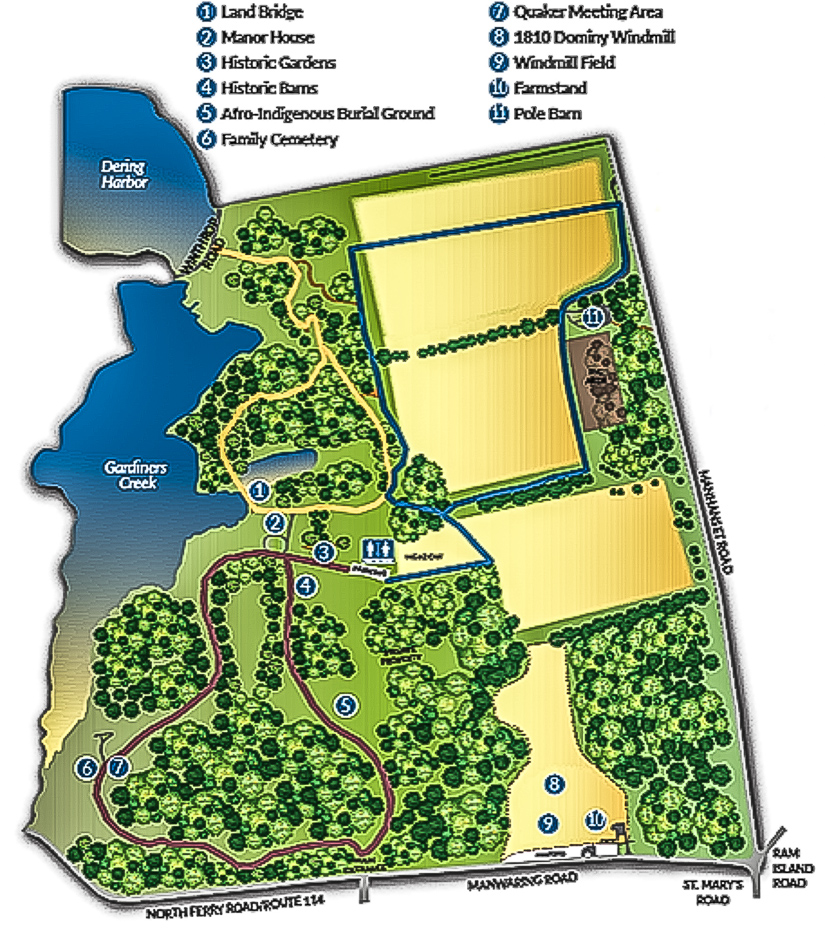

SYLVESTER MANOR EDUCATIONAL FARM

# 8: 1810 Dominy Windmill /

Sylvester Manor Windmill

__________________________________________________