Mill Pond, Water Mill

1644: Edward Howell, a wealthy miller from Lynn, Massachusetts, settled on the perfect location for a water mill, when he arrived at Southampton in 1640. It was a 100-acre pond a few miles east of the new village. By 1644, he had negotiated with the Town for 40 acres, with funding and labor, to support the construction and operation of a water mill. We think the mill was ready for grinding that year. For proper operation, a dam was created to store water for powering the wheel. The community was required to help open up a cut at the ocean beach that separated the Atlantic from Mecox Bay. This helped balance the water level downstream from the mill. The stream needed to be much lower than the water above it. This proved to be time consuming and difficult, as well as contentious.

1726: The mill was moved (and likely enlarged) several hundred yards south of where it is now, and a new dam was constructed as well as a new lane to the mill. Though Edward Howell owned the mill, he was never a resident of Water Mill and tended to his miller and other workers. William Ludlam Sr., who settled in Water Mill in 1647, bought the mill in 1653. In 1748, one of his descendants sold a half interest to weaver Elias Petty. It remained with the Ludlam family until 1760.

1790: The Mill was used for other commercial activities. The Southampton Town records record that in 1790 Hugh Smith operated a fulling mill in this building. Fulling mills took handwoven woolen cloth and made it denser and more compact. The water wheel powered several pairs of wooden mallets that pounded the fabric in water and soap filled tubs, a continuing process that could last more than a few days. This beating cleaned the natural oils and grease out of the wool and then drying would shrink the cloth to make it tight and thicker. The cloth shrinks to 1/2 its original size. The raised nap was cut smooth with heavy iron shears.

Circa 1800: Jesse Hedges and John White manufactured paper here in the early 1800s. An ad in the June 1st, 1807 edition of the Suffolk Gazette notes that, “Wrapping paper, of a superior quality may be had of Mr. John Sowden, superintendent of the paper mill belonging to White & Hedges…cash will be paid for clean linen & cotton rags.”

1825: John Benedict’s ledger records work for White & Hedges as early as 1817. In 1825, he purchases a half interest in the property of White & Hedges, including a barn, 1 1/2 acres of property, the mill and all the buildings together with the machines and other property belonging to White & Hedges. Benedict was a fuller, dyer and dresser of cloth. The partnership between Benedict and White & Hedges lasted until 1833 when John Benedict bought out his partners. His family owned the mill until 1942.

1870: Asher Benedict sued the Long Island Railroad because their culvert, under the newly laid track, was so small it restricted the flow of water to the mill. At this time a large windmill was attached to the roof to increase the power, while the suit was in the courts. Benedict won five years later and was rewarded $ 350 in damages and a new culvert.

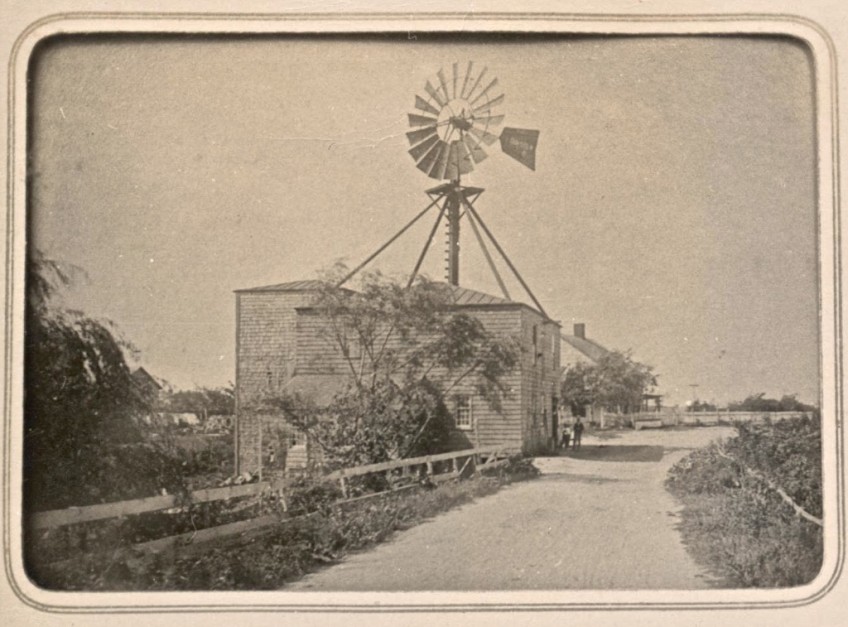

Circa 1870: The Long Island Railroad’s arrival in the east end caused a problem with the water supply for the Benedict mill. The culvert, under the tracks, was too small and did not let enough water flow through to power the Mill. Though Asher Benedict took legal action against the Railroad, the case took five years to settle. A wind mill was placed on the roof to power the Mill’s machinery, until the Railroad did the necessary repairs.

Circa 1875: This beautifully bucolic photograph pictures the Mill’s facade, as the building shades a resting worker, in early afternoon. Old Mill Lane is but a dirt path that leads to Main Street and the old windmill. The rustic fences, orchard and lush vegetation provide a rare glimpse of 19th century south fork life.

1884: A newspaper clipping reads, “F.E.Benedict Dealer in General Merchandise, Proprietor of Agawam Water & Steam Mill, special attention to grist work and manufacturer of Ice Cream.”

1890: A panorama of the hamlet of Water Mill, looking east with the Mill Pond on the left and the Water Mill almost in the middle. Cobb Road (in the center of this image) enters onto Montauk Highway, as it bends and goes toward Bridgehampton to the east.

1900: The Mill, with the Victorian-style Benedict General Store across the street, on the left.

Circa 1900: Grinding stops at the Water Mill. The Benedict family say that they can no longer make a living by grinding the small amount of grain delivered to the Mill. They are down by 90%. Ice cream becomes the big cash product of the Mill. Because of the many local dairies, and the ice harvesting on the Mill Pond, Benedict Ice Cream developed into a successful venture. It was delivered by train & wagons all over the east end for a wide range of events. The Mill was also used for overflow from the adjacent Benedict Boarding House, company laborers, and a community meeting place.

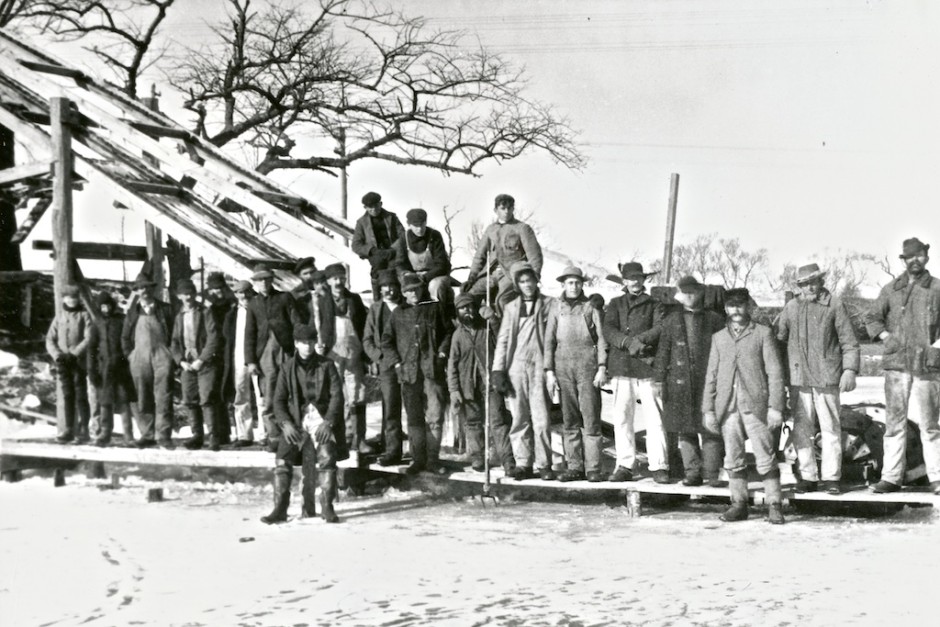

Circa 1905: These men are getting ready to cut the frozen surface of the Mill Pond and begin to harvest its ice in blocks. They are standing near the conveyor that will carry the ice into a storage barn. This is one of several conveyors that were build, over the years, by the Benedict Brothers. Ice from the pond was used when the Mill also served as an ice cream factory.

1906: Miss Alice Benedict at the bridge across the street from the Mill.

1910: The Mill and old wooden bridge as they appeared about 1900.

1918: The Ladies’ Auxiliary of Water Mill Village Improvement Society was established in 1918. They began to lease the Mill from the Benedict family in 1921. It served as a tea room and gift shop for the New York State Blind Workshop. Rent was $ 10.00 a month in 1941.

1942: On September 22, 1942, the Ladies Auixiliary of the Water Mill Improvement Society bought the Mill for $2,000 from the Benedict family. Through the 1950s the Mill was used for cooking classes, tea room and later a restaurant run by Jen Borkoski. Improvements were continually done to the building.

Circa 1955: Inside the Old Water Mill Shop & Tea Room are Jessie Modzelewski (left) and Patricia Wellinghaus admiring a woven rug. All the money raised by the sales at the Mill went to the blind craftspeople who had made the items.

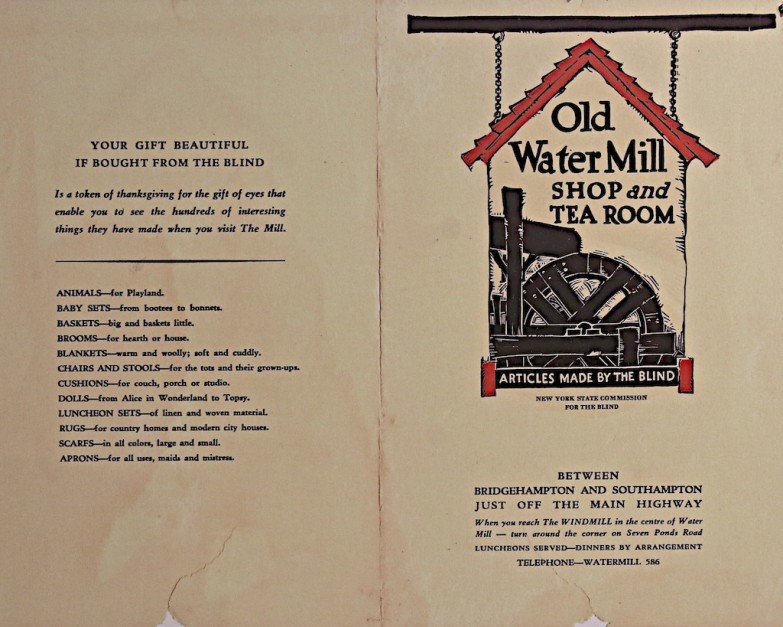

Circa 1955: The cover of a brochure printed of the Old Water Mill Shop & Tea Room. As well as selling the crafts made by the blind, luncheons were served, with dinners available by prior arrangement.

July 25, 1957: Committee of volunteer sales ladies at the Amagansett Patroness Day held at the Old Water Mill Shop & Tea Room for the NYS Commission for the Blind. Behind the ladies is a selection of the crafts made to be sold by the Blind Workshop.

1968: The Ladies Auxiliary of the Water Mill Improvement Society moved into the new era of research and restoration for this historically important building. The intention was to create a museum. After years of fund-raising, local research and using regional consultants, the painstaking process of reconstruction began. No machinery survived from the mill’s history. All were made by master craftsmen using the hand tools and materials of the mill’s past. The new water wheel was ready to grind for our nations’s bicentennial celebration in 1976.

1974: A new water wheel for the Mill. From the left: Museum Director Mrs. A. Bradford McGuire, the wheel builder Vincent King, Albert Halsey and Mrs. Vincent King.

2009: The work continues as the maintenance of old buildings is never completed. The hamlet of Water Mill supports the Water Mill Museum through fund-raising, volunteerism and community pride. The Mill is a symbol of the hamlet, its history and the preservation of what makes a group of people really a community.

—————————————————————-

MILL POND WATER MILL

——————————————————————-

Copy & Archival Images/Document Courtesy of the Water Mill Museum. Mill Pond Water Mill photo by Jeff Heatley.

www.watermillmuseum.org

———————————————————————

Visit Landmarks:

aaqeastend.com/contents/water-mill-museum-grist-mill/

Visit Capital Campaigns:

aaqeastend.com/bulletins/water-mill-museum-campaign-to-finance-internal-repairs-to-grist-mill/

___________________________________________________________________________________