CARBON CLOUD with a PLATINUM LINING

On December 22, 2008, an electrical fire burned through the center portion of a home in Water Mill. What was not destroyed by the fire itself, was ruined by smoke and water damage. Architect Richard F. Stott, a friend of the family, assembled a design/build team, which included Hamptons Green Alliance and architect Craig Lee, as a consultant, all of whom were interested in honing their sustainability skills and applying their knowledge to aid the family. The team members agreed to provide all work at cost.

The strict budget was limited to the insurance claim plus the family’s contribution for additional square footage. The LEED (Leadership in Energy and Environmental Design) checklist provided a valuable focal point, and all agreed to recycle materials, where possible, and to find sustainable solutions for every situation. Telemark, the general contractor, offered end runs and leftover lumber from other projects.

The design, drawing and permitting process took six months. After breaking ground in July, 2009, the complete renovation, with 1,500 square addition, was completed nine months later. The family moved into the new home on March 31st, 2010, fifteen months after the fire. LEED Platinum Status was awarded by USGBC (U.S. Green Building Council) in September, 2010, with 104 points, one of the highest ratings in the country.

Hamptons Green Alliance House, May, 2013

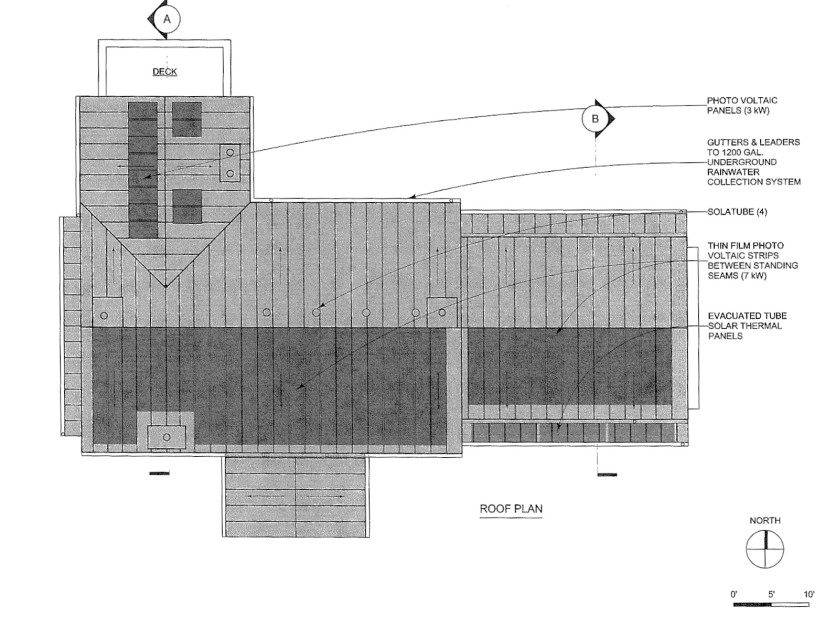

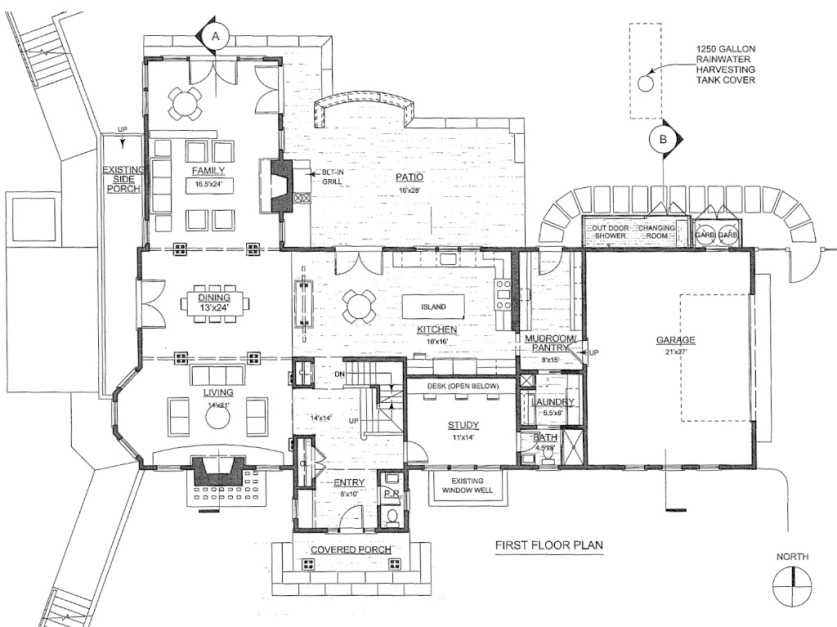

By chance, the existing home was oriented to the south. The 1,500 square feet of south facing roof offered a number of opportunities. The existing roof pitch was 8/12, or about 34 degrees, nearly perfect for our 41 degree north latitude.

Thin film photovoltaic panels fit perfectly between the ribs of a standing seam metal roof. There are two sections of roof area–the main roof and the garage roof. We extended the rafter tails to provide proper sun shading for summer sun at this latitude, which also allowed us to install 18 ft long, thin film strips. Each 18 ft strip produces 136 watts–with 36 strips, 4,896 watts could be generated. The smaller roof has 21, 68 watt strips for a total of 1,428 watts. To bring the total to 10k watts, the maximum allowable for the LIPA rebate program, we added 16 more standard type PV panels on an east facing roof, and 12 panels on a west facing roof. The four on the east roof are installed to resemble skylights and are barely visible from the ground. The 12 panels on the west roof are not visible at all from the property.

The roof plan indicates the locations of all solar systems including the standard panels on the east/west side of the master bedroom wing which make about 3 kilowatts of power and bring the total photo voltaic system to 10 kilowatts, the maximum allowed for rebates by LIPA.

The evacuated tubes mounted to the metal roof fits into the “texture” of the project.

A 214-sq ft evacuated tube solar thermal (solar hot water) system was installed on the lower garage roof. The array consists of 3-30 tube units. The total performance expectations: 105,000 BTUs daily, 3,164,000 BTUs monthly, 38,497,000 BTUs yearly. The 3-30 tube units transfer heat via a hot water manifold that circulates to two transfer units in the basement. The first heat exchanger transfers heat to a 100 gallon domestic hot water tank, the second exchanger transfers heat to a 250 gallon water storage tank, to be used for various energy needs, depending on the season and the demand. In the winter months, the heat from the storage tank is the primary source for the two zone HVAC system. Hot water is circulated to the fan coil units when one or both thermostats call for heat. If the storage tank cannot meet the demand, the system switches over to the geo-thermal heat pump as a source for heat. In the summer, the hot water storage tank supplies heat to the swimming pool after the domestic hot water tank reaches capacity. When the hot water storage tank cannot meet the pool heat demand, the system switches to the propane fired pool heater.

During the design process, we also considered using solar thermal heat for a liquid dessiccant dehumidification unit which uses latent heat in the water storage tank to dry humid inside air prior to cooling by the geo-thermal unit.

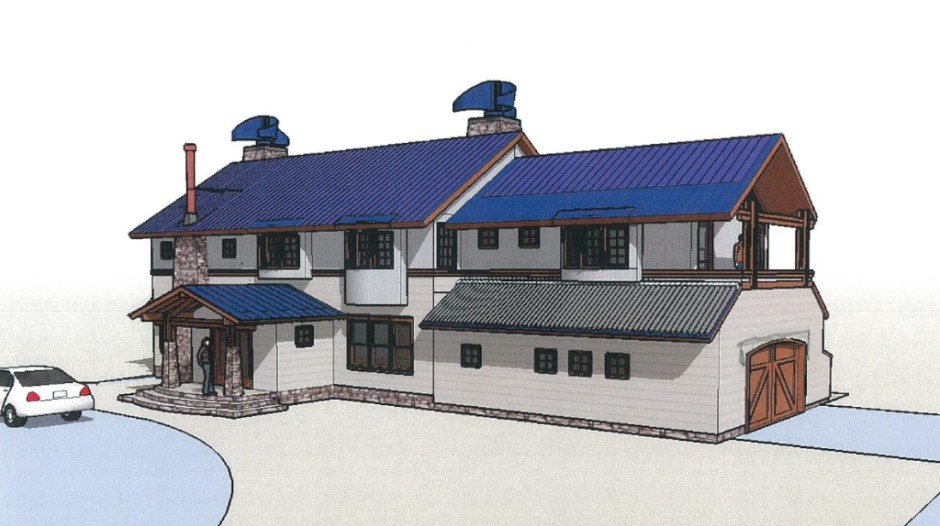

A new front entry was added which enhances the “lodge” style with rustic columns and built-in lights.

A new front entry was added which enhances the “lodge” style with rustic columns and built-in lights.

Geo-thermal heat pumps, also called water source heat pumps or ground water heat pumps, are basically air conditioning units that work in both directions; in other words, they can run in one direction, compressing a gas which changes state into a fluid as it heats and is circulated to fan coils via insulated piping in the heat mode. The fan coil blows filtered air over the hot coils, which is distributed through the building for heat. When the unit is run in the cooling mode, the fluid is pumped through an expansion tank. When the fluid expands, it cools rapidly. The cold fluid is run through piping to the fan coil units where inside air is forced over the cooling coils and distributed. The primary difference between a geo-themal heat pump and a standard air-to-air heat pump is that ground water from an open or closed loop system is used to “pre-condition” the a/c fluid. Since ground water is consistently in the 55 degree range, the latent heat can be used to reduce the temperature spread of the fluid.

East Elevation

Although the existing lawn is being replaced with “alternative turf” that requires much less maintenance, the lawn and landscaping requires a significant amount of water. Electricity is required to pump well water since this location has no public water supply. The project included a 1250 gallon water tank buried in the backyard. The gutters and leaders from the roof carry water to a filter and then to the tank where it is stored and used exclusively for landscape irrigation. This reduces the load on the domestic water use and the energy required to pump water from the on-site well.

“Solatubes” collect sunlight from four small domes on the back side of the roof. Sunlight is passed through highly reflective tubes about 10 inches in diameter and exits in the ceiling of the second floor hallway. This reduces the need for electric lighting and provides bright white daylight. The tubes are so reflective that even moon light is cast into the space at night.

The prevailing wind is from the southwest in summer and northwest in winter. We originally planned for a 2.4 kw Vertical Axis Wind generator to be placed on the north side of the main ridge on a chimney like structure. These mag wind turbines would work better in theory because the air hitting the roof plane would accelerate over the ridge. Engineers claim that an increase in velocity of up to 40% can be expected, but each installation must be analyzed with respect to average wind speed, terrain, obstacles and turbulence. The vertical axis turbine is more efficient in a turbulent and shifting air than a horizontal/propeller type turbine. During our energy analysis, it was determined that two of these units would be required to reach out Net-Zero energy goal. These were not installed because the manufacturer could not produce them in time; moreover, the local utility had not yet included these units in its rebate program, essential to remain on budget.

This is a schematic design for the pool house, which was not built. The translucent polycarbonate roof was to span a dressing/shower/bathroom, open passage way, and tool storage area. An Urban Green Vertical wind generator would provide power and be gridlinked to the public power supply.

The original home included a large cedar deck which was dismantled, denailed and saved. The 5/4 x 6 STK decking was re-sawn and cut into exterior trim including all soffit trim and the vertical strips for the upper exterior walls. The remainder of the decking was ripped in half and used on edge to construct the 2nd floor decks.

Telemark, the general contractor, had a significant inventory of left over stock from previous jobs. Cypress and white oak dimensional lumber was milled down in the shop to produce virtually all the interior trim, including window and door trim, all base and crown molding, as well as miscellaneous detail items. The original stair, which was thought to be salvageable, needed to be replaced. A number of structural glue-lams left over from a large school project fit the bill perfectly. 30″ wide glue-lams were cut up for the treads of the new stair.

All interior wood trim is re-cycled, re-purposed wood or inexpensive #2 cedar for columns and girders. The built-in lights compliment the entry.

Real stone was used inside. It supports the rustic “lodge” style and warms the space.

This stair was constructed entirely from re-purposed, glue-laminated lumber.

HAMPTONS GREEN ALLIANCE HOUSE

The tragedy caused by an electrical fire in December, 2008, gave way to one of Long Island’s most recognized sustainable homes. This Certified LEED Platinum project broke ground just 9 months after the original house burned down. The reconstruction included a 1,500 square foot addition, while integrating multiple renewable energy systems including a 100,000 kw thin-film photo voltaic system built into the roof, solar water heating for domestic hot water and pool heating, a geothermal heat pump and rainwater harvesting.

This Hampton Green Alliance house was certified Carbon Neutral by VERSUS-Carbon Neutral Partnership and awarded a 95+ HERS (Home Energy Rating System) rating – a score considered unattainable for an addition/renovation project of this size. The original residents moved back into their home in March, 2010, and use approximately 50% less energy than the original 3000 sq ft home, even with the 1,500 sq ft addition.

The New York State Legislature issued a Legislative Resolution in recognition of the HGA House design team’s efforts “…to promote green building and maintenance practices…”

Content copy provided by architect Richard F. Stott.

——————————————————–

The HGA House Design Team

Lead Architect/Designer:

Richard F. Stott, AIA, LEED AP, Steelbone Design, Southampton, NY. 631.283.1777. www.steelbone.com

Consulting Architect:

Craig Lee, AIA. Lee Architecture. Sag Harbor, NY 11963. 631.725.9468. www.leearchitecture.com

General Contractor:

Tim Dalene, LEED AP. Telemark Construction. Bridgehampton, NY 11932. 631.537.1600. www.telemarkinc.com

Plumbing:

Ken Maher. Excelsior Plumbing. Westhampton Beach, NY 11978. 631.283.8383. www.excelsiorplumbing.com

HVAC:

Rick Blydenburgh. Flanders Heating and Air-Conditioning. Riverhead, NY 11901. 631.727.2760. www.flandershvac.com

Electrical:

Steve Bartick. Bartic Electric. Westhampton Beach, NY 11978. 631.567.4295

Landscaping:

Roger Feit. Treewise Inc.. East Hampton, NY 11937. 631.324.4239. www.treewiseorganics.com

Solar Equipment:

Geof Marshall. Sunstream Solar. Southampton, NY 11968. 631.283.0057. www.sunstreamusa.com

Smart House Consultant:

John Thorsen. Connected Hearth. East Hampton, NY 11937. 800.575.3479. www.connectedhearth.com

_____________________________________________

For further information on energy-saving options, visit Hamptons Green Alliance: www.hamptonsgreenalliance.org.

The Hamptons Green Alliance (HGA) is a not-for-profit association of building and related-service professionals in the Hamptons on Long Island organized to promote green building and maintenance practices. HGA provides information on materials, systems and best practices for building, maintaining carbon neutral, zero energy homes and ecological landscapes via its website and other public forums.

————————————————

Photos: Jeff Heatley, May, 2013